Amaray Plastics: How Lean Manufacturing Drives Profits In a Streaming World

Produced by Brian Mooney

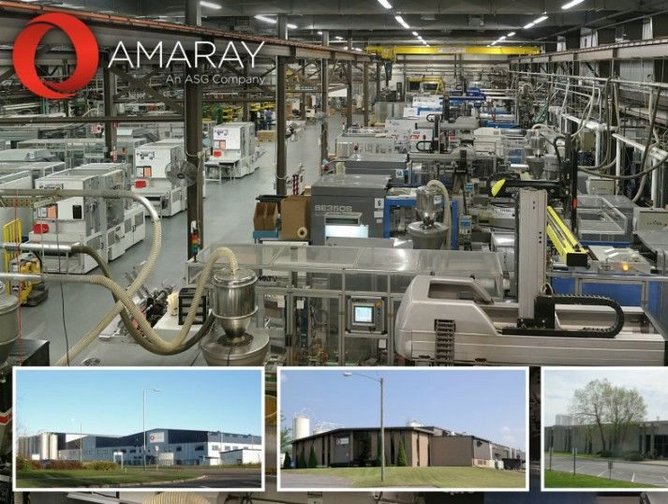

As one of the highest volume producers of plastic components and assemblies, Amaray Plastics knows its business is driven by customer experience and therefore sets out to achieve extreme customer satisfaction as a focused solutions provider bringing insight, innovation and cost effective manufacturing alternatives within select markets where need for millions or billions of parts produced to exacting, repeatable tolerances exists.

Amaray’s multinational manufacturing operations, working to standardized processes and procedures, enable them to provide all levels of project support with consistent quality and production outputs. Customer service, quality, advanced manufacturing technology, an informed, engaged workforce and innovation serve as the pillars for the company.

As part of Greenwich, CT based Atlas Holdings, Amaray is a well-funded organization poised for growth and diversification. As the long term, global leader in the molding of polypropylene boxes for discs that contain movies, games and software, Amaray is one of the best companies in the world at high volume, highly automated, highly efficient injection molded plastic products. Now Amaray is charting new courses for growth and diversification leveraging the foundation that has led to its success in their primary market.

Jim Sykes was brought aboard as President and CEO in April 2014 to lead the growth charter. Sykes, a recognized industry leader, was employed by Nypro Inc. for the prior 22 years. In a variety of commercial and operational roles, he successfully spearheaded new Nypro business growth in the consumer electronics space from its inception to nearly $700M annually. “Amaray has amassed 323 patents spanning 25 countries in the area of media package manufacturing,” shared Sykes. “The standard polypropylene box today is 42 percent lighter than 10 years ago. Innovation and continuous improvement is the genesis of where we come from.”

Profitability in a Streaming World

A decade ago, media packaging was the main source of revenue for dozens of companies around the world. However, with the growing movement of people acquiring content digitally, the industry is now experiencing erosion.

“We're a company in transition,” said Sykes. “Our roots are in the manufacture of home entertainment or media packaging.

“Amaray is one of the few global injection molders that have been able to sustain profitably in this space. We will continue to focus on this massive market, increasing share and extending product and service offerings. We have formed and empowered a dedicated global team of commercial and technical talents to forge and execute our winning strategies on this front. As in all of our multinational enterprise, we will maintain our competitive advantage through innovation, ingenuity, customer orientation Lean manufacturing processes, and increased integration of automation.”

Progressive Lean strategies have helped with this transition.

“Amaray's drive into Lean manufacturing stems from the aggressive market demands that we were under in the home entertainment or media packaging world,” said Sykes.

Employees are trained in Lean concepts and team events are held regularly to engage everyone in the process. Over the past few years, Amaray’s Lean journey has included Kaizen events targeting particular areas of opportunity. The organization also maintains formal, robust, cross functional continuous improvement and 5S programs. These programs involve every department within the company, but generally have registered the most profound impact in the manufacturing area. Ted Brown, a 13 year Amaray veteran, was responsible for originating many of the companies structured efficiency programs over the years. Recently, Brown was promoted from VP North America to the global Chief Operations Officer role. Brown commented “Aggressively driving opportunities for operational efficiency gains, waste reduction and lower cost has long been part of the Amaray DNA. Our formal programs in this regard, now in their 11th year, continue to evolve and gain momentum. They have been the cornerstone of our success here at Amaray.”

Although Amaray remains profitable in the media market, the company has turned an aggressive focus toward diversification. Dedicated business development and program management resources with strong experience and networks in new industries were hired in both Europe and USA in 2014. These folks are charged with the responsibility of securing additional products and customers that will benefit from the ultra-precision, low labor content manufacturing environment. Primary applications sought will likely involve technologies which Amaray has pioneered in the Media market; living hinges, snap closures, high volume products lending themselves to highly automated secondary operations.

Jamie Tinsley, Managing Director of Amaray Europe added “The team focused on Develop and Diversify is now in place across Europe and the USA; a blend of creative, innovative and commercial talent with a broad experience across many sectors, focused entirely on the delivery of new products, developing new market sectors and adding value for Amaray and its Customers. We have set ambitious targets as far as business forward growth plans, but the focus and drive shown over the past couple of quarters is delivering tangible benefits. We encourage market leading brands to talk with us, challenge Amaray to review its products, packaging and services and let us show you how Amaray can add value.”

Technology like InterNetworX’s ShopWorX ERP manufacturing software package helps Amaray’s Elizabethtown, KY and Pittsfield, MA facilities with planning, manufacturing, scheduling, costing, accounting and customer support. InterNetworkX tailored ShopWorX ERP specifically for the company to help develop automated palletizing as well as a warehouse inventory control system utilizing barcoding to minimize labor while maximizing accuracy. Amaray’s finished goods inventory accuracy has increased from sub 90 to 99 percent+ since the implementation.

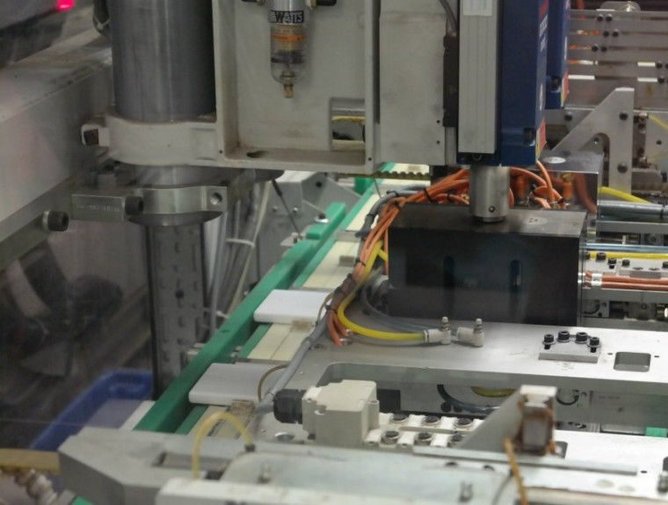

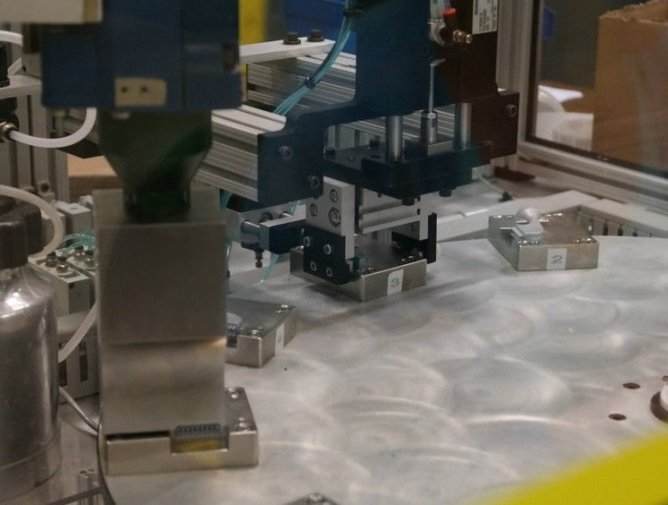

In addition, Amaray continues to increase their value added manufacturing services connected to the molding machine via an in-line, automated approach. Hot stamping, pad printing, ultrasonic welding, thermal welding, In-Mold Labeling (IML), mechanical assembly and PSA application are all conducted at the molding machine, within cycle time with zero labor content. Ted Brown stated, “Over the years we have demonstrated a nearly flawless track record in integrating new technologies and ramping them to high volumes within project time and cost constraints.”

Meeting its organic growth and acquisition goals will help Amaray remain profitable in the digital era. The company is poised for acquisitions. In the short term Amaray is actively seeking to purchase smaller injection molding companies in Western Europe and North America where adjacent capabilities or solid customer relationships can be obtained.

Green Partnership with Major Studios

As mentioned earlier, a big part of Amaray’s business is customer satisfaction. One of the company’s latest green initiatives was prompted by listening and responding to customer requests.

One of major objectives of the film studios is to fill the retail pipeline channels with movies and TV shows. However, filling these channels is based on demand speculation. If consumer demand doesn’t meet expectations, studios must take back the unsold products.

“That take-back of inventory was causing pain among our major customers, the studios that produce these pictures,” said Sykes. “Based on that pain point, Amaray, three years ago, instituted recycling centers within our major U.S. and UK operations.

“What happens now, the undersold product from the market comes back to the Amaray factories where we do a complete tear down and then we re-grind and re-process the plastic materials back into new cases.”

For The Future

Amaray has very ambitious plans for growth and is preparing to triple in size over the next five years. Sykes expects that half of this growth will be organic from current factories; the other half will potentially be through strategic acquisitions that will be complementary to Amaray’s services.

“To sustain, increase share and remain profitable in this market, it comes down to: how can we continuously innovate, optimize manufacturing efficiency and drive lowest system cost?” With leverage on raw materials unlike we’ve seen at any other company and a laser focus on customer satisfaction, Amaray is in a good position to meet these aggressive goals.