Flowserve 2.0 and the journey to supply chain transformation

Space is a premium commodity on a floating production, storage and offloading unit (FPSO). Offshore oil and gas is a key market for Flowserve, which leads the world when it comes to flow control, but outside that industry it's not always understood what a critical role pumps, valves and actuators play on a production platform, nor the amount of room these take up on an oil rig.

“The most expensive real estate in the world is the back of an offshore platform,” says Ronaldo Marques, Vice President – Supply Chain, and he should know, having over a 25-year career led strategic procurement and supply chain for some of the most recognized O&G companies. These include Texaco, Chevron, and most recently Shell, where he was responsible for an annual spend of $9bn. He joined Flowserve in April 2017, attracted by the opportunity to make a real difference in a company that recognized the need to integrate its supply chain operations and bring this vital aspect of the business into the heart of its strategic decision making.

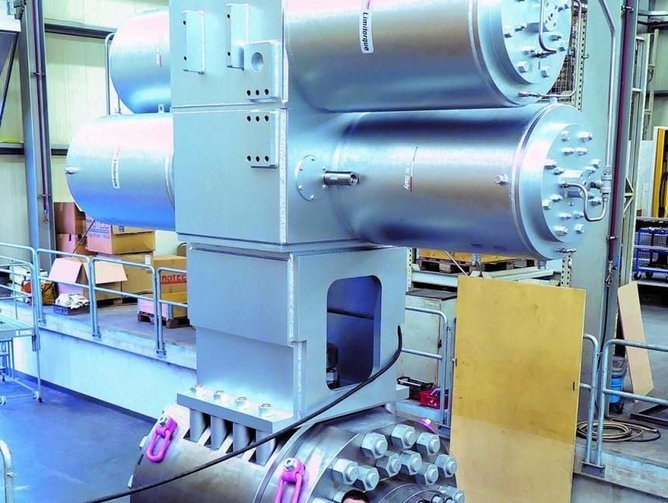

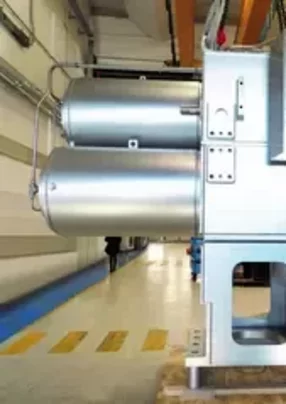

Let's look again at the FPSO example. Pumps and valves are the core of the equipment, but the smart part of the installation is the actuator which controls the flow. More than a million of Flowserve's Limitorque division actuators have been installed around the world, and some have been in operation for more than 50 years. Their ruggedness and reliability are legendary. Recently a client constructing a new FPSO found there was not enough space on the platform to accommodate the large conventional actuator selected to operate it. The Flowserve design allowed construction of the FPSO to proceed according to the originally planned layouts, with no need for costly and invasive redesign. It also ended up saving around 2,000 kg (4,400 lb) in weight. Usually, production modules on FPSOs are installed in close proximity, explains Marques. “Because FPSOs carry refinery-grade heavy equipment on a marine vessel, managing weight translates directly into savings in capital expenditure. Lowering weight by just one ton (2,200 lb) can result in construction savings of $30,000 to $50,000.”

This result had everything to do with supply chain management, he points out. Not supply chain alone, but in alignment with engineering and suppliers. It's quoted because it represents clearly the value proposition offered by Flowserve. “Because we work with engineering we save a whole lot on materials,” says Marques.

When he joined Flowserve, at the same time as its new CEO and President R Scott Rowe to whom he reports direct, the global organization was very fragmented. With 17,000 employees at 254 locations in 55 countries, and four major business platforms each under its own President , procurement was being carried out on a local, or at best national basis. There were some very good pockets of excellence but there was clearly a huge opportunity to be seized. He and Rowe were of one mind, that integration across the business could yield huge benefits, and noticeably better outcomes for its customers. Their plan has been to deliver strategic change through supply chain transformation.

Marques’ enthusiasm for this task is boundless. “The important thing is that we are aligning ourselves with the business. As we transform our supply chain and integrate across all platforms and business segments globally, we will simplify processes and save a lot of money. We will eliminate waste from double handling, simplify processes and procedures, standardize, then automate big time. We need to refocus the local and global organization, work with robust leadership teams, and our human capabilities worldwide.”

The job of rationalizing the supplier base has already been started over the last 10 months, reducing their number but working with these in a more collaborative way. “Until now we've approached our suppliers from the inside-out, so to speak – we tell them what to do, sometimes not in a very collaborative way. We are going to change that to an outside-in, aligning people, processes and technology with our key suppliers to create value in a flexible strategic supply chain. We are going to deploy tools and systems to enable the supply chain data and then drive the accuracy and analytics, with a mindset of continuous improvement and the ruthless elimination of manual process.”

This is not reinventing the wheel, and he admits that eliminating duplicate activities, identifying and sharing best practices and encouraging the local teams to own these continuous improvements may look simple. But in a complex global organization it takes time to roll out these ideas. This plan was endorsed by the top leadership team from the get-go, and the roadmap to global supply chain alignment by 2020, the road to Flowserve 2.0, was an early outcome. “The most exciting thing is that nine months down the line we have full endorsement from every leader from corporate HR, IT, finance and so on, and also from the platform presidents of every division. It is no longer a supply chain plan: it is their plan – a Flowserve corporation plan. That is critical.” The value proposition is so powerful, he adds, that it has been bought into by the entire business. “Flowserve 2.0 is the turnaround of Flowserve and my job as part of the leadership is to transform Flowserve's supply chain so it's the most admired and competitive in the entire industrial manufacturing industry.”

The company already has a powerful suite of tools. The basic supply management system comes from a trusted partner, Zycus, with whom Flowserve has been collaboratively rolling out modules to the global sites. “We are leveraging that technology, which will give us valuable visibility, data storage, data analytics and the like. We have plenty of data within the company but what is it telling us? We partner with Zycus to drive improvements on top of the data whether elimination, simplification, standardization, supplier rationalization or renegotiation.”

Flowserve also uses Zycus for contract management. There is nothing simple about writing and executing strong, favorable and risk-minimizing legal contracts with suppliers. Many parties need to be involved, and the complexities multiply rapidly when contracting at enterprise levels – across locations, strategic business units (which are often distinct legal entities) and across global regions and sovereign borders. The iContract system smooths out these complexities. Over the last six months Marques has visited every one of the company's manufacturing sites in China, India, Europe and Australia to explain and facilitate the learning needed to get these systems working in an integrated way. Another good example of a vendor that assists integration and the taming of raw data to assist decision making is Mihlfeld & Associates (M&A), which makes sense of the huge bulk of logistics data that's available. “We have more than a million logistics invoices a year so we work with M&A on technology to audit, analyze and pay these invoices – and we continuously improve on that,” Marques adds.

The plan is delivering. Flowserve 2.0 is on its way. 2017 targets were reached with two months to spare. “We are not driving an initiative, we are driving a full service strategy. We are driving cross-platform change in areas like indirect spend and logistics. We listened to the business leaders and the VPs, sales and operations people and the plant managers, and we adapted our plans to drive their plants. What's not to like? On top of that we layered in the corporate initiatives, the cross platform initiatives and then the roadmap that I presented, together with the whole strategy, to the board. They gave us full and unanimous support.”

A major win for strategic sourcing was a drive to rationalize the global payroll. 46 countries were served by 38 different suppliers and internal HR resources, so consolidation was a must. The plan had been to make phased changes, with Europe, the Middle East and Africa sorted out over two years and Latin America following in 2019. “I got the guys together, and said why don't we do this all at once?” Marques adds. The result was unbelievable, enabling not only all the business requirements but also introducing automation, AI and other available technologies using a very disciplined process. Impacting 15,000 employees, HR is now consolidated in one supplier, one system. The implementation is going to be 80% complete in 2018, saving 30% on the projected cost.” He is already working on how to reduce the cost to serve for the other corporate functions by similar margins, with direct impact on the bottom line.

So, Flowserve is well on its way to becoming a data-driven business, a business with growth on its agenda. The supply chain plan will not be different from the corporate plan. At a recent Flowserve 'summit' of 100 leaders, the supply chain alignment story was delivered by the President. “We drew up the presentation together,” says Marques. “I don't need to talk about supply chain because the business is talking about supply chain. This is Nirvana.”