How Dynegy has recovered from its tumultuous past with a huge expansion and vastly improved supply chain

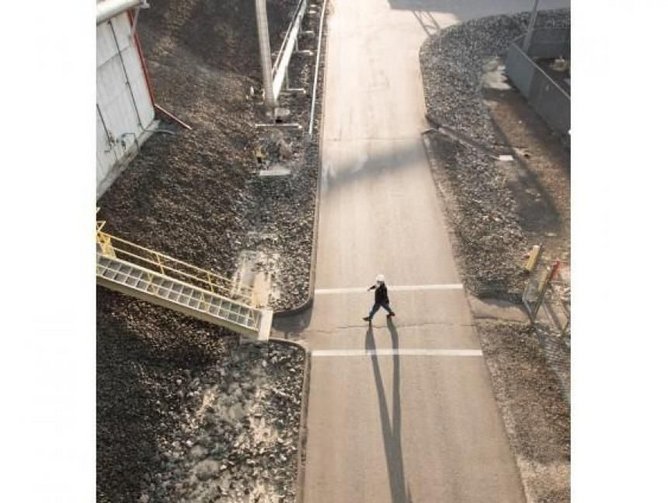

The Houston-based independent power producer (IPP) has 50 generating facilities in 12 states throughout the Northeast, Mid-Atlantic, Midwest and Texas. Dynegy has transformed from a coal-heavy portfolio of plants largely dependent on one power market, to one that is geographically diverse, generating more than 31,000 megawatts (MW) that are predominately natural gas-fueled – capable of producing enough energy to power the homes of 25 million U.S. families.

Managing the supply needs of a group of this size can be a challenge. Shaun Anderson, Dynegy’s Managing Director of Supply Chain, explains how altering some of the most basic processes proved critical to driving down operational costs.

“When I started two years ago, there was no supply chain organization,” he says. “Instead, a procurement group used a transaction-based process where a group of buyers would support the needs of each site individually. Recognizing there was an opportunity to put a purchasing strategy in place, we first established a true supply chain organization with three value streams of Strategic Sourcing, Supply Chain Services and Procurement.”

Instead of setting up a centralized group to dictate to the rest of the company how things work, Dynegy’s approach is center-led. The team actively gathers input from members of the operations group to meet collective goals with standardized processes across the business. It focuses on leveraging and optimizing spending across the company, instead of just addressing opportunities on a site level.

Dynegy’s supply chain group tailors the way it operates to meet specific business needs. Setting the company apart from others in the industry, Anderson has a ‘source-to-pay’ (S2P) process in place, rather than the standard ‘procure-to-pay’ (P2P) approach.

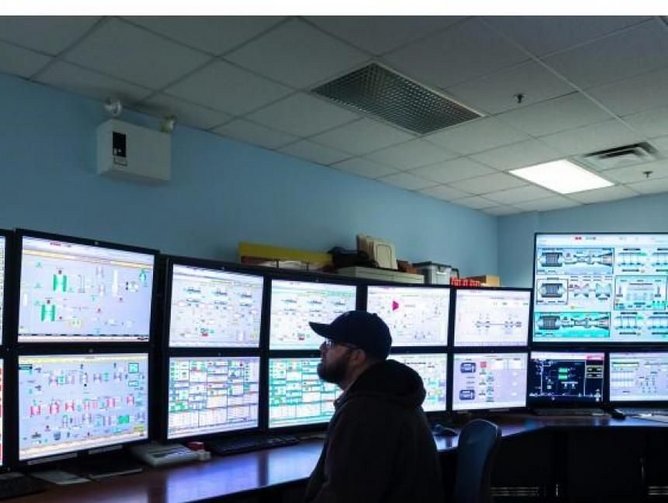

“I intentionally named it ‘source-to-pay’ to build in strategic thinking about sourcing as an early part of the process,” says Anderson. “The added step at the beginning gets our supply chain group involved even earlier to add even more value across the organization. Also, we initially had multiple systems within systems as part of the P2P workflow. Now we use one common system, Maximo, to streamline activities.”

The S2P process has been a key challenge to implement, but also a significant source of improvement to Dynegy as an organization. By the third quarter of this year, Anderson expects the S2P process to deliver significant efficiencies throughout the entire work flow, including operational site-level needs, inventory, work order creation, requisitions and purchase orders.

Dynegy has grown through a number of strategic acquisitions in the last several years. As might be expected, some initial push-back was present early on as cultures came together from different companies. To help manage the change involved with shifting to a different way of doing business, cross-functional teams were developed to enable strategic sourcing, regular meetings with key administrators, policy changes and other activities.

A key element of the company’s drive towards integration is the ‘voice of the customer’ program, which ensures customer needs are heard and addressed to become part of the process.

“The VoC program is where we have monthly meetings with the key administrator of each site,” explains Anderson. “We not only talk about things we’re trying to do differently and changes we’re implementing, but we also get feedback from them as our internal customers on what’s working and what isn’t. We’ve had tremendous feedback in terms of the recent company changes.”

In sitting down with Dynegy’s cross-functional team members across the operations group and asking for advice from their perspectives, Anderson and his team can gather an accurate reading of how the company is performing. Similarly, there is now a center of excellence team which goes beyond the supply chain, where operational members can makes alterations on a policy level. “We utilize this team as a sounding board not only to get feedback on change, but also to help communicate and drive that change forward,” Anderson says.

“Opposing cultures is an inherent challenge of company change,” he adds. “Dynegy is unique in that we have put things in place to address this from the first day an employee joins the company.”

For a company to be successful, it needs to win the hearts and minds of its people. ‘Inspired Energy’ is Dynegy’s program designed to consciously create a culture. The initiative is a system of shared language and concepts to build an environment allowing employees to be at their best. The program sets a tone to enable people to build camaraderie and focus on the task at hand. It helps them realize they each have a part in the company’s success and that their individual contributions matter.

“Inspired Energy ensures how people do things is as important as what they do and is based on Dynegy’s organizational values,” he says. “Every employee goes through an initial Inspired Energy orientation, followed by a training several months later. The Inspired Energy culture gets everyone is working on the same page. This type of change management at a foundational level is definitely an asset as we move forward.”

Despite of the growing pains common with the kind of expansion Dynegy has experienced, the company is positioned for longevity and sustained success. With a strong, strategic focus concentrated on improving business processes, systems and tools while leveraging spend opportunities, the supply chain organization works on continuous end-to-end improvement that emphasizes total cost of ownership, and the integration of critical suppliers into business solutions for a lean, agile and responsive process.

“We’re making sure we have the right systems in place that align with the business,” says Anderson. “Just like Dynegy as a whole, the supply chain organization has gone through a transformation. We are intentionally integrated focus on aligning business needs with corporate objectives while providing added value, efficient processes and cost-saving throughout the company. Dynegy prides itself on being a lean organization that succeeds because we have the ability to get more out of less. We work smart and take full advantage of the technology we have at our disposal.”