Every day billions of items, from fresh foods to mobile phones, move through complex supply chains all across the world. At some point or another, many of these goods rely on shipping pallets; a simple, unassuming tool, but one which has helped to revolutionize supply chains and encourage e-commerce growth since they were first introduced. Now, with the help of RM2, it seems that shipping pallets are revolutionizing the industry once more.

With its cutting-edge BLOCKPal™ pallet, RM2 has established itself as an innovator in pallet design, manufacture, supply and logistics management. Boasting a more reusable, durable design, and harnessing the Internet of Things (IoT), the BLOCKPal pallet is helping to enhance supply chains by making them more sustainable, cost-effective, and traceable. Using leading expertise and technological prowess, RM2 is transforming how we ship items, and it seems that the company’s innovative ethos is at the heart of its success.

“At its core, I would characterize RM2 as a research and development company,” explains Paul deRoulhac, EVP of Global Supply Chains at RM2. “We spent the early years of our existence really focused on material engineering and the manufacturing process, and the result of that was a shipping pallet that was head and shoulders above everything else that had ever come into the market.”

Durability and Strength

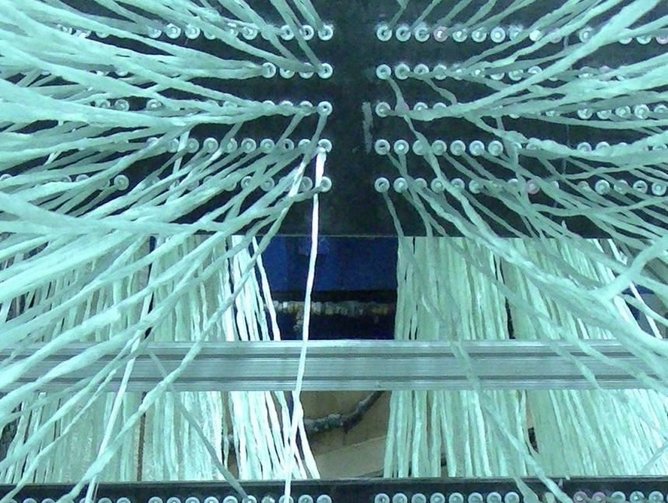

Comprised of state-of-the-art composite materials, the company’s flagship BLOCKPal pallet offers remarkable strength that goes far beyond anything else in the material handling sector. This durability not only reduces product damage, worker compensation, and system downtime, it also ensures that the pallet has a longer life cycle and is more cost-effective.

“Virginia Polytechnic Institute and State University conducted extensive tests on the BLOCKPal pallet,” notes deRoulhac. “According to the Center for Packaging and Unit Load Design at Virginia Tech, the BLOCKPal pallet outperforms industry standards and can sustain upwards of 150 rugged trips* before requiring maintenance or repairs, resulting in an ISO 8611 and ASTM 1185 accredited pallet.”

“To put that in perspective, one-way traditional wooden pallets last approximately 3-5 trips, whereas the unique modular design of the BLOCKPal pallet makes it easy to repair,” he adds. “Combined with the ability to track and trace which eliminates loss, the RM2 pallet has the potential to become an infinite asset.”

Helping to Achieve Sustainability Goals

Wooden pallets are a critical building block of modern-day supply chains, with billions currently in circulation. Broken or damaged pallets often end their life cycle in landfill sites and so the BLOCKPal pallet not only offers a cost-effective alternative, it also helps customers achieve sustainability and environmental goals.

“Our BLOCKPal pallet is also about 25% lighter than a comparable block pallet and this really promotes fuel savings and efficiency from a weight standpoint,” comments deRoulhac. “The process of moving pallets around is also much more efficient because we can get 630 unloaded pallets into a truck versus standard block pallets where there can only be about 540 in a load. In this way, we're reducing weight, the number of trips, the number of deliveries, and the number of trucks on the road, which is having a positive environmental impact.”

The connectivity of the RM2ELIoT Smart Pallet to the AT&T LTE-M network unlocks the benefits of the reusable BLOCKPAL pallet. Pure Strategies, a US sustainability consulting firm, conducted a peer-reviewed life cycle assessment comparing the environmental impacts of the BLOCKPal pallet to those of a standard multi-trip wooden pallet**. Utilizing this data, AT&T has conducted a case study on the RM2 Smart Pallet called ‘Unlocking the Potential of Connected, Reusable Pallets.’***

This study concluded that the connectivity of the RM2ELIoT Smart pallet enables the user to potentially avoid 640 metric tons of CO2 per year, which is equivalent to 72,000 gallons of gas for every 1 million pallet trips. Based on this study, if just 5% of the estimated 10 billion worldwide pallets switched to the reusable RM2ELIoT pallet, it could drive a reduction of 7.3 million metric tons of CO2 or 818 million gallons of gasoline per year.

*Virginia Tech operates a specific regime of test trips designed to replicate pallets being used in an extremely rough handling environment.

** http://bit.ly/2yFHEi2

Health and Safety

From retail to the pharmaceutical industry, the BLOCKPal pallet is suitable for many major operations. One sector where the pallet is particularly useful is the food and beverage industry. As a result, the company is keen to address one of the industry’s most pressing concerns - health and safety.

“Designed from FDA and USDA approved material, the pallet is completely impermeable to water as well as bacteria,” says David Kalan, RM2’s VP of Marketing and Business Development. “From a hygiene standpoint, this reduces contamination risks as bacteria can’t penetrate the material plus the pallet can be easily cleaned with a basic industry wash process. I would say our pallet is a vast improvement over wood variations. In this way, hygiene and cleanliness are a huge selling point for our platform.”

“Based on the nature of the materials that we're using, it's also fire retardant, which is a factor in the pallet space,” adds deRoulhac.

With Dow as a key partner to RM2, the company is able to operate at the cutting edge of material science to evolve the RM2 pallet and further enhance the customer’s experience. With full access to the Dow product portfolio and their continual assistance in RM2’s R&D program, using cutting-edge composite research is redefining the global standard for logistics innovation.

*Virginia Tech operates a specific regime of test trips designed to replicate pallets being used in an extremely rough handling environment.

** http://bit.ly/2yFHEi2

The Smart Pallet

The BLOCKPal pallet boasts a range of admirable qualities but perhaps its most impressive feat is that it is embedded with a RM2ELIoT, a wireless device that communicates to the Internet of Things, turning it into a smart pallet. Working closely with AT&T, the company has developed an Electronic Link to the Internet of Things, commonly known as RM2ELIoT. This is a track and trace monitoring device which aims to advance pallet and supply chain security, all whilst meeting the demands of the fourth industrial revolution.

By responding to industry trends such as IoT, the company has remained ahead of the curve, offering a pallet which allows shipments to be tracked precisely from point A to point B. Through this innovation, RM2 is helping to drive actionable intelligence which will encourage efficiency in supply chains.

Knitted into the very fabric of the BLOCKPal pallet, the ELIoT software is completely maintenance free, dynamic, and flexible. “The pallet triggers a signal through the AT&T network - an IoT signal - that's composed basically of five data elements: latitude, longitude, date, time and pallet ID,” deRoulhac explains. “Those data elements are transmitted when a pallet starts moving, if it's delayed in transit, and when it arrives at its final destination. That gives you a very granular view of everything that has happened between the two traditional data points that you used to get - shipped and received.”

As well as this, the pallet also captures shock events and temperature, which offers visibility and transparency to supply chains. “If the pallet experiences a shock event, you'll know the exact date, time, and physical location of when it happened,” says deRoulhac. “Therefore, you can ascertain who was in possession of the pallet at the time and you can react accordingly. It gives much more visibility into events that were, up until this point, probably binary.”

Easy Application

Pallets may seem like an unassuming tool, but at RM2, the team is helping to revolutionize the industry by harnessing the potential of new technologies such as the Internet of Things. However, whilst this technology may transform the supply chain discipline for the better, it doesn’t need to overhaul a company’s internal infrastructure. Indeed, one the most surprising aspects of this innovation is its easy application.

“I think one of the key attributes that we're bringing to the market is that it's really a turnkey solution, in that there's no additional infrastructure required,” explains deRoulhac. “The pallet is basically self-contained, the communication is self-contained, and we can very easily make that level of data available to our customers. We're really replacing something that already exists within the supply chain today, a shipping pallet, and able to deliver an IoT solution with no upfront implementation costs or infrastructure expense.

By embracing technological trends and cutting-edge design, RM2 has proved that although shipping pallets may seem like a simple tool, they can have a significant impact if utilized effectively. “With this technology, our objective really is to drive actionable intelligence that can help drive efficiency in the supply chain,” deRoulhac says, “I think, ultimately, that’s what our pallet solutions are doing.”

Total Pallet Management

RM2 is not just delivering a smart pallet, it also provides a total pallet solution through a comprehensive logistic network. Programs are designed to meet the individual company’s needs which include both internal and external loops. With the support of logistics partners such as SCR Air, who is constantly striving to provide the best in class service while delivering the best possible cost, RM2 is able to deliver a nationwide logistics network that supports its client’s solutions.