Van-Rob: Auto manufacturing visionaries

Formed in 1979, Van-Rob is a Tier One supplier to the major automobile manufacturers. The company is an industry leader in the design and manufacturing of metal stampings, modular welded assemblies, structural welded assemblies, mechanical assemblies and heat shields for thermal applications.

As a full-service supplier, Van-Rob is known for technology, product design, service and delivery – it’s the staple of their brand. The company has received numerous awards from clients such as General Motors, Ford, Visteon, DaimlerChrysler, International Truck, Subaru and Auto Alliance.

Along with innovative designs and technology, Van-Rob’s company culture has played a pivotal role for the company’s success. By placing importance on its people and nurturing a working environment characterized by mutual respect, Van-Rob is pursuing a healthy balance between people and technology, putting them at the forefront of the auto industry.

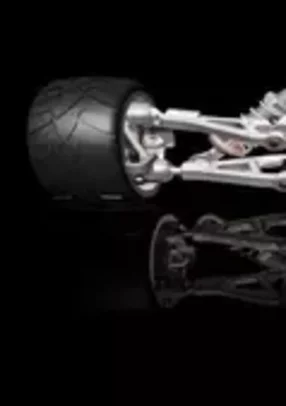

Imagination, innovation, and technology

Technology and innovation is a way of life at Van-Rob. The company is at the forefront of the automotive industry in imagination, innovation and technologically-advanced automotive systems and complex modules.

Van-Rob has introduced a state-of-the-art servo-mechanical press, where stroke length, curve, and speed are optimized to produce high quality parts with reduced tool wear. Resistance spot welding optimization is based on using simulation modeling techniques in conjunction with experimentation. These methodologies have been developed and perfected in-house by Van-Rob.

The company is known as innovators in the industry because of their experienced staff and industrial engineers. The company’s engineers have introduced new and innovative systems in the area of MIG welding, and with the assistance of harmonization of robots, weld-power sources and wire feeds, the company is delivering world-class results such as improved tolerance in aluminum and steel, as well as reduced deformation. Engineers have also developed manufacturing cells in a cross-function environment following strict APQP functions. These cells are optimized for the most efficient use of floor space, containerization, error proofing, inventory and ergonomics.

Van-Rob’s ‘Design for Cost’, a term embraced by the company’s Product Design Group, has helped the company design for manufacturability and on-time delivery as well as helping produce innovative products designed for minimum cost. The company makes extensive use of laser welding and laser cutting where such applications make economic sense on a volume production basis. Van-Rob engineers work closely with equipment suppliers to ensure new applications are optimized with respect to new and existing laser technologies.

Solid teamwork

With over 300 employees and 11 facilities within Canada, US and Mexico, Van-Rob has grown into a multi-plant global organization operating from more than a million and a half square feet.

Van-Rob accredits its past success to its greatest asset, its people. The company places a great deal of importance on its people and strives to provide opportunities for the personal growth and advancement of their people. Van-Rob believes in promoting from within and many of the company’s management personnel have worked their way up to their current positions from other levels within the company. The company demonstrates its loyalty to employees by investing in them through various training programs, helping to accelerate their career advancement. The company’s commitment to long-term partnerships with its people will allow Van-Rob to secure its future.

The company subscribes to various manufacturing practices such as lean and Kaizan as part of its overall culture. Van-Rob implements many training programs to provide employees with the necessary skill levels to support the continuous improvement efforts that customers require to sustain growth and prosperity. These extensive training programs include, management training, apprenticeship programs, 5S and Kaizen workshops.

The goal at Van-Rob is to surpass customer expectations in quality, service, price, delivery, and technology – it’s as simple as that. The company does so by entrusting in its commitment of management and employees. Van-Rob utilizes open and honest communication to continuously challenge itself to improve its processes, products, and services. Communication between various facilities is considered essential to the promotion of team work, and Van-Rob is committed to establishing a work environment in which all employees have the ability to work and contribute to their maximum potential.

Workplace health and safety is essential at Van-Rob. The company’s efforts are supported by plant health and safety teams through monthly audits and 5S practices to eliminate the possibility of injuries. Facilities are fully equipped with first aid stations, Occupational Health Nurses and Registers Practical Nurses, which help promote wellness within the company as well as facilitate health and safety programs.

Environmental policies

Along with being a leader in the automotive industry, Van-Rob continuously strives to implement eco-friendly practices. The company diligently works to establish and maintain its environmental system’s foundation of prevention, legislation, documentation, implementation and communication. The company works to develop an environmental structure by setting objectives and goals to improve and review its practices and processes in pollution prevention and waste reduction. By actively working to reduce the negative environmental impacts of its activities, products, and services, Van-Rob is exceeding applicable legislation and other requirements to which the company subscribes to.

Van-Rob has recently opened a new facility in Texas where it will continue to invest into equipment, research and design, and its people. As a leader in the auto manufacturing industry, Van-Rob is always going to find new ways to innovative and transform the industry for the better, whether it’s through new equipment, employee training programs or eco-friendly practices.