Door Dash reaches $7.1bn valuation with $400mn funding round

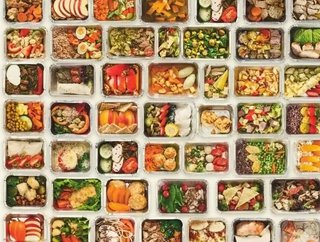

On-demand delivery company DoorDash, headquartered in San Francisco, announced this week that it has raised a further US$400mn. The funding, raised in a Series F financing round, was lead by Temasek and Dragoneer Investment Group with participation from existing investors Softbank Vision Fund, DST Global, Coatue Management, GIC, Sequoia Capital, and Y Combinator.

Following the capital injection, DoorDash has reached a market valuation of $7.1bn. The investment will be used to further accelerate the company’s growth strategy, from 250% over the past 12 months to 325% over the course of 2019, cementing its position as the fastest-growing company in a sector it shares with on-demand giants like Uber Eats, Deliveroo, Grubhub and Postmates.

Over the past year, DoorDash expanded its coverage to more than 3,300 cities in all 50 United States and Canada.

SEE ALSO:

-

Starbucks partners with Uber Eats, expands delivery service to six additional cities

-

Uber in talks to acquire European food delivery startup Deliveroo

-

Click here to read the February edition of Business Chief USA

“Last year, the culmination of more than four years of work came to fruition as we expanded our geographic footprint by over five times across the U.S. and Canada, launched and scaled DashPass to become the largest food delivery subscription product in our industry, and expanded beyond restaurants through our DoorDash Drive platform,” said Tony Xu, co-founder and CEO of DoorDash.

The company’s DoorDash Drive last-mile logistics platform partners with businesses beyond the food and beverage sector to provide on-demand delivery services in partnership with companies like Walmart, Chipotle, Denny’s, Wingstop and Portillo. The subsidiary is expected to pass a $1bn valuation in the next year.

- Asset Panda CEO Rex Kurzius on Innovating and Taking RisksLeadership & Strategy

- Snowflake: Powering the next generation of startupsTechnology & AI

- Fortune shines a light on the companies ‘changing the world’Sustainability

- The legacy of Walmart International CEO Judith McKennaLeadership & Strategy