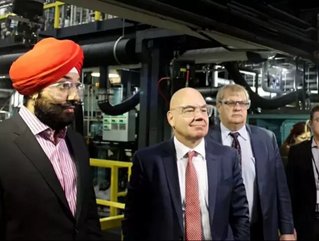

[PHOTO] Minister of Science Navdeep Bains visits Xerox Research Centre

Cooperation and interest between the public and private sector is an important part of a healthy economy. This month Navdeep Bains, Minister of Innovation, Science and Economic Development provided an example of this interest with a visit to Ontario’s Xerox Research Centre of Canada to explore some of the manufacturing innovations under development at the location.

RELATED CONTENT: Amazon Web Services names Montreal as site for first Canadian data centre

“Today’s tour of the Xerox Research Centre of Canada was an impressive demonstration of the great R&D that is taking place here in Mississauga,” said Bains in a statement addressing the visit. “Through its investment in the XRCC, Xerox Canada is making an important commitment to developing the kind of innovative and ground-breaking products that will help transform and improve the lives of Canadians, while also reinforcing the strength and innovative capacity of Canada’s manufacturing sector. My tour, along with the roundtable discussion with the Association of Canadian Manufacturers and Exporters, has shown me that Canada’s manufacturers are capable of tremendous, and potentially ground-breaking innovation.”

One important innovation under development at the Research Centre is “printable electronics,” a technology that can allow other manufacturers a way to inexpensively create smart products using Xerox’s conductive silver nanoparticle inks. This kind of development is progress for not just Xerox, but other Canadian businesses that can use this technology to grow and make new ideas a reality.

RELATED CONTENT: Canadian businesses look to optimize communications

“Innovation is a critical success factor for Canada’s long-term economic resilience,” said Dr. Paul Smith, Vice President, Xerox Research Centre of Canada. “We have a long-standing commitment to supporting Canada’s capacity to innovate and commercialize research outcomes. We were very honoured to show Minister Bains some of the work we are doing in advanced materials research and the partnerships – including the creation of the Canadian Campus for Advanced Materials Manufacturing with the National Research Council Canada – that we are developing to help Canadian start-ups commercialize their ideas right here in Canada.”