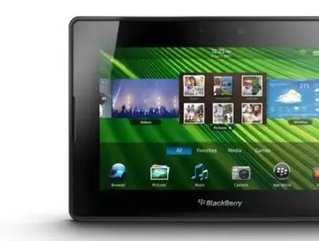

RIM Recalls BlackBerry PlayBooks

RIM announced a recall of 1000 of its recently released 16-gigabyte version of the PlayBook BlackBerry tablet due to an installed faulty operating system (OS). The faulty OS prevents users from downloading software as well as inhibits setup processes. PlayBook users can go to this Crackberry link to view the full list of recalled PlayBooks by serial number.

According to a statement released by RIM, the majority of the affected devices were still at retailers and haven't reached customers. RIM also is offering troubleshooting assistance for PlayBooks that are unable to properly load software upon initial set-up. However, PlayBooks with that particular issue are not being recalled.

The Huffington Post released the full statement given by RIM, seen below.

"RIM determined that approximately one thousand BlackBerry PlayBook tablets (16 GB) were shipped with an OS build that may result in the devices being unable to properly load software upon initial set-up.

The majority of the affected devices are still in the distribution channel and haven't reached customers. RIM is working to replace the affected devices.

In the small number of cases where a customer received a PlayBook that is unable to properly load software upon initial set-up, they can contact RIM for assistance."

SEE RELATED STORIES FROM THE WDM CONTENT NETWORK

First Day Blackberry PlayBook Sales Better Than Expected

University Scientists Develop Flexible Smartphone

GlobalEnglish Understands International Business Relations

Read the latest Business Review Canada!

This recall is unfortunate considering that the PlayBook was RIM's first foray into the new competitive market of tablet computers currently controlled by Apple. However only time and the consumer response will tell if the PlayBook, despite this hiccup, will be a viable contender against the iPad. RIM says PlayBook shipments in the quarter continue to be in line with its expectations, but the company hasn't said how many units it expects to ship in the quarter ending May 28.