True Fit comes to Macy's for more efficient shopping

For the women in your life who need more tools on ways to spend your money comes True Fit, a new personalization software that helps customers know how well clothes and shoes will fit in real life and what size will work best. Macy’s will be the first retail partner to use the technology for its online customers, specifically for women shopping the denim collection.

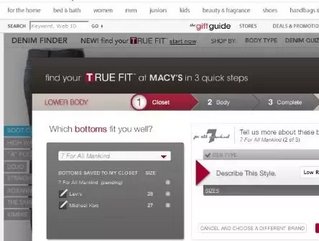

How it works:

Customers create their True Fit profile once, in 3 quick steps: First, customers identify what fits them from their own closet; second, they identify conceptual body descriptions; and third, they complete their profile with some basic info – no measurements necessary.

True Fit’s novel machine learning software deploys a variety of patented and proprietary algorithms to analyze massive amounts of data from the user’s profile, shopping behavior, catalog of products, and a variety of other robust data inputs to deliver highly personalized fit and size recommendations in real time. The result is a highly personalized shopping experience that tailors a catalog to each person’s individual fit, enabling men and women to shop a retailer’s site True to YouTM for all categories of clothing and shoes.

The user then instantly sees True Fit recommendations for each product they view:

· True Fit T-ScoresTM – a five-point scale that indicates how well the item will fit

· True Fit SizeTM – the best size recommended and pre-selected for that user

· True Fit DetailsTM – fit details across key body areas such as waist, hips, seat and inseam

“We’re thrilled to partner with Macy’s – a venerable retailer and innovation leader, who is on the cutting edge of defining the very best experience for the multi-channel shopper. We’re excited to deliver this highly personalized service to their esteemed customers, and make it easier for them to find the right clothes and shoes at Macy’s,” said William R. Adler, True Fit’s CEO.

“Macy’s is a recognized industry leader, committed to implementing the newest technological advancements that will resonate with our customers,” said Kent Anderson, macys.com president. “By partnering with True Fit, we are able to provide a unique online shopping experience that brings a new level of personalization and service to customers that shop macys.com.”

True Fit users overtime will improve the way they shop and become more efficient when it comes to clothes buying. Additionally, retailers are hoping to benefit from the new software as existing and future customers will learn what styles work best for them and hopefully will return for new purchases. True Fit will be available on mobile and iPad platforms, allowing for easier in-store shopping. For more information, visit www.TrueFit.com.

- Five CEO appointments in the US you may have missedLeadership & Strategy

- Salesforce: global online sales reach an all time highTechnology & AI

- IBM study identifies global consumer trends for the holidaysSustainability

- Target Canada: Online Stores Are The Least of Its ProblemsDigital Strategy