Gartner: AI-based guided selling improves sales execution

Sales leaders are facing unprecedented changes in B2B buying behaviours, customer expectations, technology and the talent needed to drive results. And many of these changes have been brought about by COVID-19 with traditional forms of guided selling having undergone considerable change.

“The pandemic exposed cracks in many organisation’s sales processes,” says Tad Travis, research VP at Gartner, and as a result, sales leaders have increasingly looked into how AI can enable improved sales results.

“Knowing that sales process discipline must be improved to increase the chances of closing new deals, sales leaders are investigating new data-driven, AI-based guided selling functions for improving sales execution.”

Gartner analysts say that traditional forms of guided selling, both as a sales process methodology and as technology, have proved to be limited. They lack a data-driven approach and do not provide statistically relevant recommendations that guide sellers to win deals.

AI-based guided selling has transformed guided selling capabilities

According to Gartner, B2B sales organisations should help sellers improve sales execution and increase the chances of closing new deals by adding AI-based guided selling to their sales technology stack.

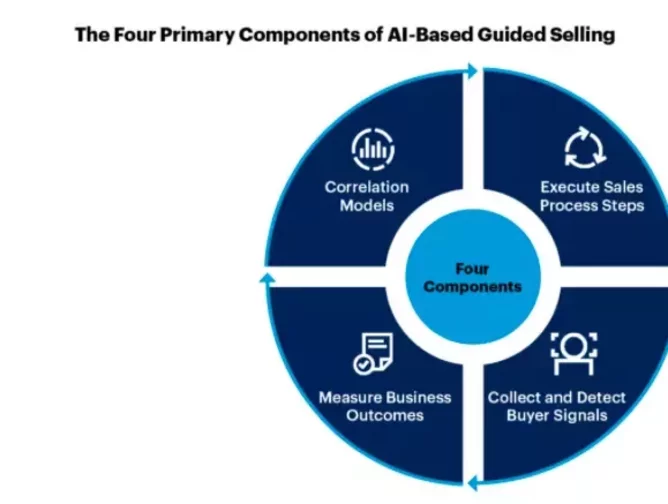

AI-based guided selling has four main components and comes in two forms:

- Prescriptive – recommended next best actions that reveal statistically relevant indicators about sales process steps

- Predictive – insights that reveal statistically relevant indicators about sales process steps

Therefore, rather than requiring sellers to decide what to do next to move a relationship, deal or quote forward, sellers can instead rely on statistically derived analytics.

And while the “value proposition of AI-based guided selling is undeniable”, says Travis, “it is not an immediate solution for better sales execution, as organisations with data quality or process issues may not be able to take advantage immediately”.

Implementing AI-based guided selling

Before implementing AI-based guided selling, Gartner recommends that sales leaders follow the below four actions, with more guidance available in its report, Optimise Sales Execution with Artificial Intelligence for B2B Guided Selling

- Educate all sales partners on the foundational elements of AI-based guided selling, focusing on the importance of collecting the microlevel actions of engagement that sellers undertake within the span of an active deal.

- Identify sales process steps and business outcomes that are unique to the organization’s processes to find the best-fit solution.

- Update the sales technology roadmap by selecting the form of AI-based guided selling technology that is most relevant to the sales organization’s lead, opportunity, sales enablement and quote management use cases.

- Prioritize where AI-based guided selling functions would be most relevant by identifying the parts of the organization’s sales value chain that are prone to the highest amounts of human-educated guessing, or that require the most amount of business rule evaluation.